Waste to Resources

Waste is not a Waste but a Misplaced Resource

– Turning Wastes into Resources for Civil and Environmental Applications

X. He, C.C.Y Ling, Z. Sun, X. Xu, F. Y. Li, X. Wang, H.T.W. Tan, Mohamed Lokman Mohd Yusof, Subhadip Ghosh, Chi-Hwa Wang, “Sustainable management of water hyacinth via gasification: Economic, environmental, and toxicity assessments”, Journal of Cleaner Production, 372, 133725b (2022). “Water hyacinth gasification, which generates syngas and biochar, is a promising thermochemical approach for bioenergy production and greenhouse gas mitigation. We investigated the economic feasibility, life-cycle greenhouse gas emission and human toxicity impact of two different water hyacinth gasification approaches: water hyacinth with and without wood chips. ”

X. He, Y. Wang, M. H. Tai, A. Lin, S. Owyong, X. Li, K. Leong, M. L.M. Yusof, S. Ghosh, C.H. Wang, “Integrated applications of water hyacinth biochar: A circular economy case study”, Journal of Cleaner Production 378, 134621 (2022). “Water hyacinth (WH) gasification, which generates syngas and biochar, is a promising thermochemical approach for bioenergy production and greenhouse gas mitigation. In this study, three different WH gasification biochar applications have been demonstrated: agricultural soil amendment, activation for activated carbon, and augmented concrete generation.”

Y. Wang, G. Lin, X. Li, M. H. Tai, S. Song, H. T. Wah Tan, K. Leong, E. Y. B. Yip, G. Y. C. Lee, Y. Dai, C.H. Wang, “Meeting the heavy-metal safety requirements for food crops by using biochar: An investigation using sunflower as a representative plant under different atmospheric CO2 concentrations”, Science of the Total Environment, 867, 161452 (2023)

WASTE FROM INCINERATION

Both carbon black waste and ash are the unavoidable by-products produced in huge amounts by incineration of industrial wastes. Carbon black waste is produced from gasification of crude oil bottoms whereas ash is a residual component of sewage sludge and municipal solid wastes after incineration. If not reused, they will be sent to Singapore’s only landfill, Semakau Island. However, these materials contain toxins like heavy metals, polycyclic aromatic hydrocarbons (PAHs), etc at high level concentration which can potentially pose adverse environmental impacts to the surrounding aquatic systems. Re-utilising the wastes by turning those into resources are therefore important to ensure more sustainable management of the solid wastes.

Tai, M.H., Mohan, B.C., Yao, Z. and Wang, C.H., 2022. Superhydrophobic leached carbon Black/Poly (vinyl) alcohol aerogel for selective removal of oils and organic compounds from water. Chemosphere, 286, p.131520.

One recent development from the research team is using the treated carbon black waste to make lightweight, highly porous sorbent or so-called aerogel for separation of oils and organic compounds from water. Carbon black waste contains numerous tiny pores which provide abundant site for sorption. However, carbon black waste in powder form is difficult to separate after use which restricted its application.

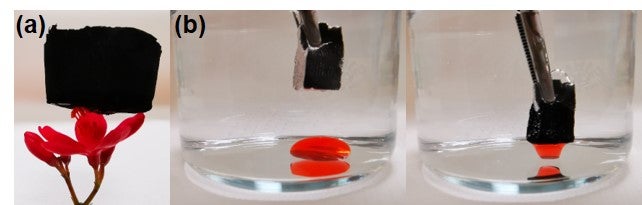

(a) Low density carbon-based sorbent rested on a flower petal. (b) Underwater oil adsorption by the sorbent.

The 3-dimensional aerogel constructed by the research team eases the separation and collection for reuse. Moreover, after appropriate surface modification, the aerogel poses superhydrophobic property that makes it effectively repel water while absorbing oils and various organic compounds. Taking the advantage of its superior selectivity and high porosity, the aerogel could adsorb up to 35 times its original weight. Through a simply drying method, the used aerogel could be readily recovered and reused repeatedly. The aerogel developed by Professor Wang and his research team has high potential application in remediation of oil spills and oily wastewater treatment.

Lin, W.Y., Prabhakar, A.K., Mohan, B.C. and Wang, C.H., 2020. A factorial experimental analysis of using wood fly ash as an alkaline activator along with coal fly ash for production of geopolymer-cementitious hybrids. Science of The Total Environment, 718, p.135289.

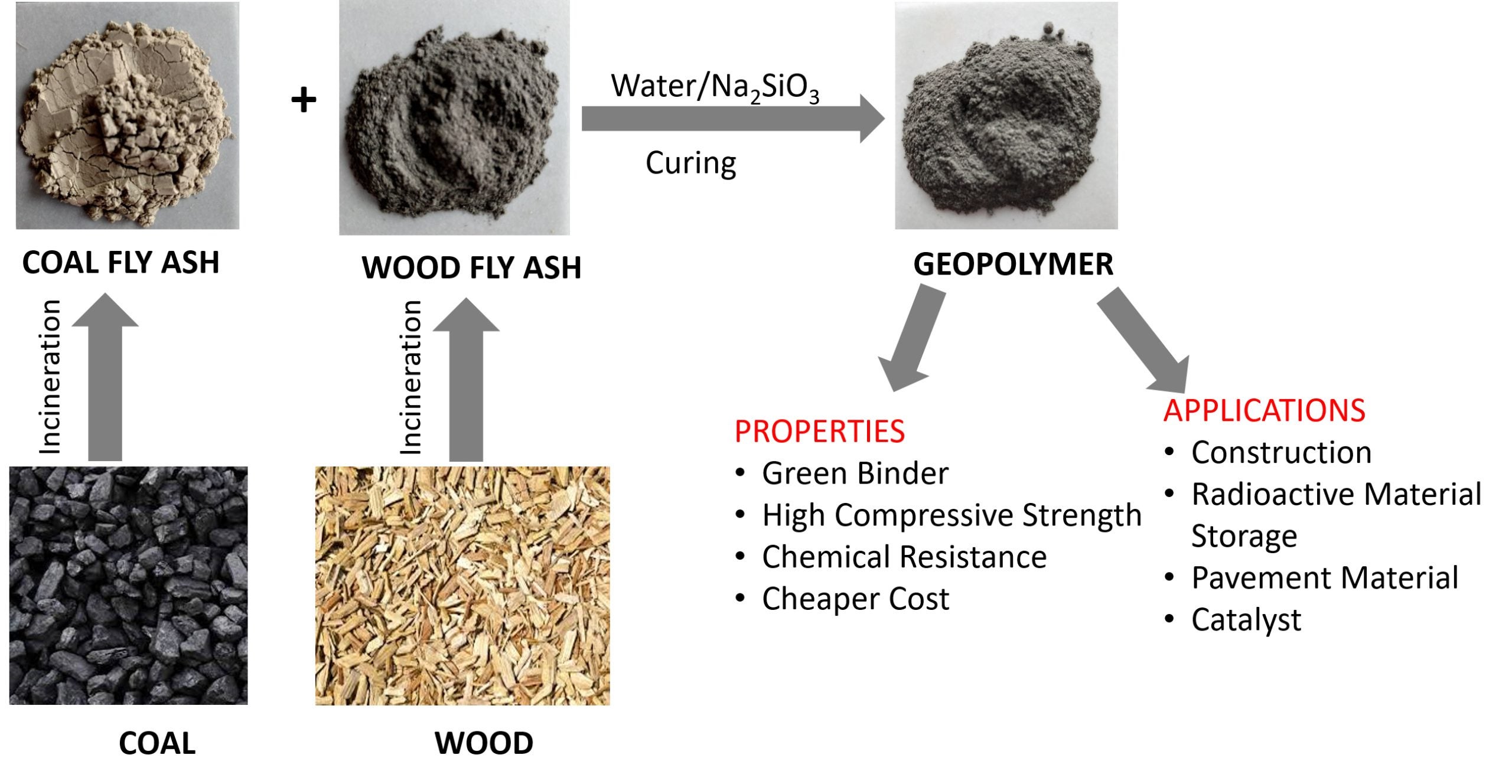

Professor Wang and his research team are also exploring the use of wood fly ash as an alkaline activator for the production of geopolymer (a greener alternative to cement, using coal fly ash). Usually an external activator like sodium silicate is used for the geopolymer production, which increases the cost of the process and requires skilled handling. Here wood fly ash is used as an activator which reduces the overall cost and also facilitates ash recycling. Various process parameters were tuned and formulations were tried using internal/external activators and it was discovered that using wood fly ash alone resulted in geopolymer production that leached out the least in terms of heavy metal. A cost estimation analysis showed that the produced material is cheaper than the conventional cement used in concrete and is thus promising.

Our research project On this topic can be found here.

T. Maneerung, S. Kawi, C.H. Wang, “Biomass Gasification Bottom Ash as a Source of CaO Catalyst for Biodiesel Production via Transesterification of Palm Oil”, Energy Conversion and Management, 92, 234-243 (2015).

The main aim of this research is to develop environmentally and economically benign heterogeneous catalysts for biodiesel production via transesterification of palm oil. For this propose, calcium oxide (CaO) catalyst has been developed from bottom ash waste arising from woody biomass gasification. Calcium carbonate was found to be the main component in bottom ash and can be transformed into the active CaO catalyst by simple calcination at 800 °C without any chemical treatment. The obtained CaO catalysts exhibit high biodiesel production activity, over 90% yield of methyl ester can be achieved at the optimized reaction condition. Experimental kinetic data fit well the pseudo-first order kinetic model. The activation energy (Ea) of the transesterification reaction was calculated to be 83.9 kJ mol-1. Moreover, the CaO catalysts derived from woody biomass gasification bottom ash can be reutilized up to four times, offering the efficient and low-cost CaO catalysts which could make biodiesel production process more economic and environmental friendly.

T. Maneerung, J. Liew 2, Y. Dai 3, S. Kawi, C. Chong, C.H. Wang, “Activated carbon derived from carbon residue from biomass gasification and its application for dye adsorption: kinetics, isotherms and thermodynamic studies”, Bioresource Technology, 200, 350–359 (2016).

T. Maneerung, J. Liew 2, Y. Dai 3, S. Kawi, C. Chong, C.H. Wang, “Activated carbon derived from carbon residue from biomass gasification and its application for dye adsorption: kinetics, isotherms and thermodynamic studies”, Bioresource Technology, 200, 350–359 (2016).

In this work, activated carbon (AC) as an effective and low-cost adsorbent was successfully prepared from carbon residue (or char, one of the by-products from woody biomass gasification) via physical activation. The surface area of char was significantly increased from 172.24 to 776.46 m2 g-1 after steam activation at 900 °C. The obtained activated carbons were then employed for the adsorption of dye (Rhodamine B) and it was found that activated carbon obtained from steam activation exhibited the highest adsorption capability, which is mainly attributed to the higher surface area and the abundance of hydroxyl (−OH) and carboxyl (−COOH) groups on the activated carbon surface. Moreover, it was also found that the adsorption capability significantly increased under the basic condition, which can be attributed to the increased electrostatic interaction between the deprotonated (negatively charged) activated carbon and dye molecules. Furthermore, the equilibrium data were fitted into different adsorption isotherms and found to fit well with Langmuir model (indicating that dye molecules form monolayer coverage on activated carbon) with a maximum monolayer adsorption capability of 189.83 mg/g, whereas the adsorption kinetics followed the pseudo-second-order kinetics.

L. Rong, T. Maneerung, J. C. Ng , K. G. Neoh, B. H. Bay, Y. W. Tong, Y. Dai, C.H. Wang, Co-Gasification of Sewage Sludge and Woody Biomass in a Fixed-bed Downdraft Gasifier: Toxicity Assessment of Solid Residues, Waste Management, 36, 241-255 (2015).

As the demand for fossil fuels and biofuels increases, the volume of ash generated will correspondingly increase. Even though ash disposal is now strictly regulated in many countries, the increasing volume of ash puts pressure on landfill sites with regard to cost, capacity and maintenance. In addition, the probability of environmental pollution from leakage of bottom ash leachate also increases. The main aim of this research is to investigate the toxicity of bottom ash, which is an unavoidable solid residue arising from biomass gasification, on human cells in vitro. Two human cell lines i.e. HepG2 (liver cell) and MRC-5 (lung fibroblast) were used to study the toxicity of the bottom ash as the toxins in the bottom ash may enter blood circulation by drinking the contaminated water or eating the food grown in bottom ash-contaminated water/soil and the toxic compounds may be carried all over the human body including to important organs such as lung, liver, kidney, heart, etc. It was found that the bottom ash extract has a high basicity (pH = 9.8 – 12.2) and a high ionic strength, due to the presence of alkali and alkaline earth metals e.g. K, Na, Ca and Mg. Moreover, it also contains concentrations of heavy metals (e.g. Zn, Co, Cu, Fe, Mn, Ni and Mo) and non-toxic organic compounds. Although human beings require these trace elements, excessive levels can be damaging to the body. From the analyses of cell viability (using MTS assay) and morphology (using fluorescence microscope), the high toxicity of the gasification bottom ash extract could be related to effects of high ionic strength, heavy metals or a combination of these two effects. Therefore, our results suggest that the improper disposal of the bottom ash wastes arising from gasification can create potential risks to human health and, thus, it has become a matter of urgency to find alternative options for the disposal of bottom ash wastes.

Morphology of HepG2 cells at different time points (24 h, 48 h and 72 h) after exposure to extracts of bottom ash from 20% Sludge + 80% Wood Chips after the extracts was neutralized by nitric acid. The scale bar in each panel is 50 μm.

Z. Z. Yang, S.K. Koh, W.C. Ng, R.C.J. Lim, H.T.W. Tan, Y.W. Tong, Y. Dai, C. Chong, C.H. Wang, “Potential Application of Gasification to Recycle Food Waste and Rehabilitate Acidic Soil from Secondary Forests on Degraded Land in Southeast Asia”, Journal of Environmental Management, 172, 40-48 (2016).

Gasification is recognized as a green technology as it can harness energy from biomass in the form of syngas without causing severe environmental impacts, yet producing valuable solid residues that can be utilized in other applications. In this study, the feasibility of co-gasification of woody biomass and food waste in different proportions was investigated using a fixed-bed downdraft gasifier. Subsequently, the capability of biochar derived from gasification of woody biomass in the rehabilitation of soil from tropical secondary forests on degraded land (adinandra belukar) was also explored through a water spinach cultivation study using soil-biochar mixtures of different ratios. Gasification of a 60:40 wood waste-food waste mixture (w/w) produced syngas with the highest lower heating value (LHV) 5.29 MJ/m3—approximately 0.4-4.0% higher than gasification of 70:30 or 80:20 mixtures, or pure wood waste. Meanwhile, water spinach cultivated in a 2:1 soil-biochar mixture exhibited the best growth performance in terms of height (a 4-fold increment), weight (a 10-fold increment) and leaf surface area (a 5-fold increment) after 8 weeks of cultivation, owing to the high porosity, surface area, nutrient content and alkalinity of biochar. It is concluded that gasification may be an alternative technology to food waste disposal through co-gasification with woody biomass, and that gasification derived biochar is suitable for use as an amendment for the nutrient-poor, acidic soil of adinandra belukar.