Overseas Researcher Invitation WRH Program

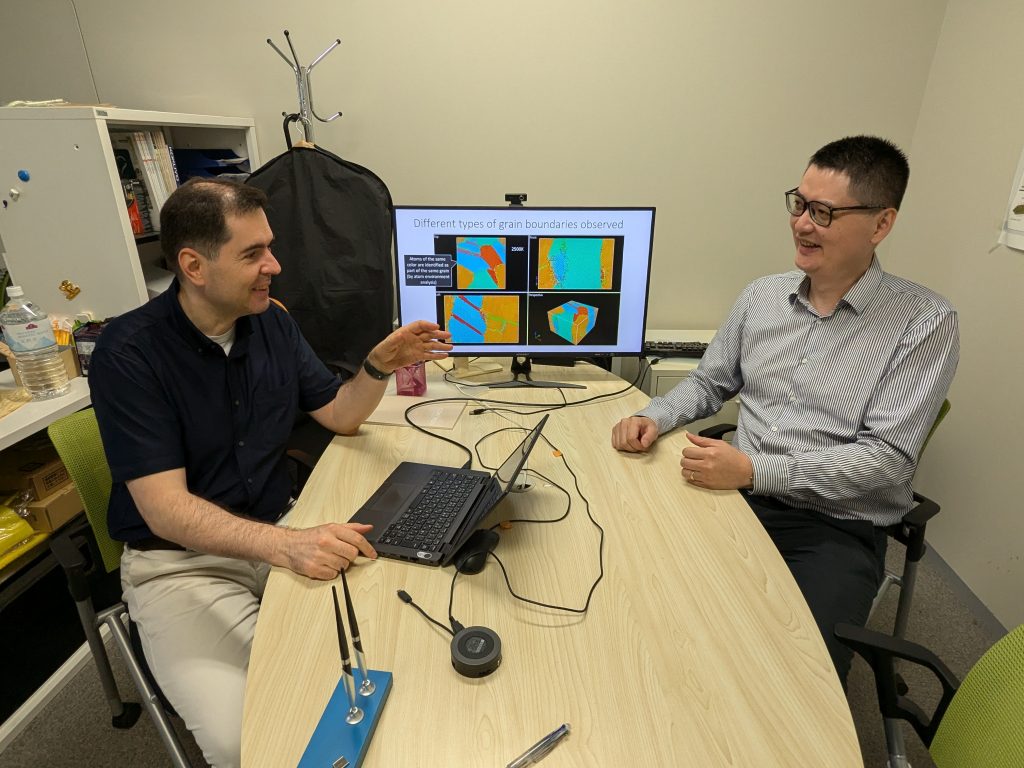

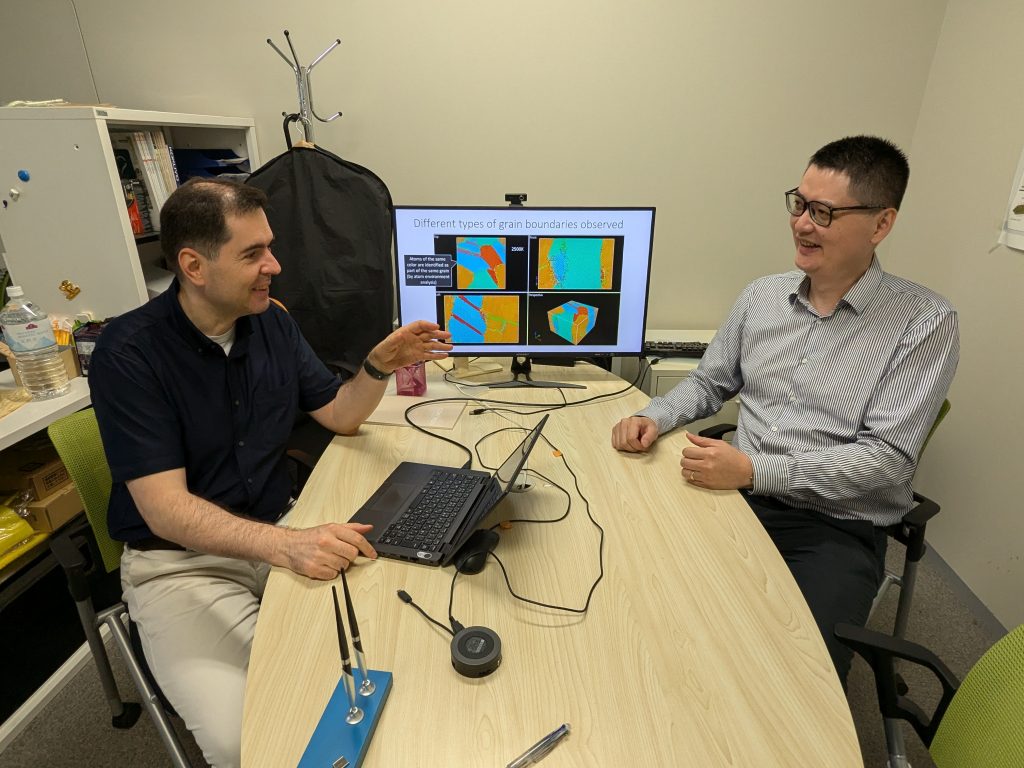

The World Research Hub (WRH) Program is driven by the International Research Frontiers Initiative (IRFI) at Tokyo Institute of Technology to host world-class researchers at Tokyo Tech for international collaborations. Assoc. Prof. Wang was warmly welcomed as an Overseas Researcher by Assoc. Prof. Sergei Manzhos to collaborate on a joint research project titled Investigation of microstructure-driven properties of functional ceramics: from large-scale atomistic calculations to experimental validation.

The collaboration with Assoc. Prof. Manzhos from the School of Materials and Chemical Technology, Tokyo Institute of Technology, was established to achieve the goal of combining the expertise of atomistic materials modeling in Ihara-Manzhos lab, and the mechanical property characterization of functional ceramics with molecular dynamics (MD) simulations and experimental micro/nano-testing in NUS, to deliver both theoretical and computational understandings on the developments of microstructural elements and material properties.

Hosting colleagues from Pen-Tung Sah Institute of Micro-Nano Science and Technology (IMNST), Xiamen University

We were honored to host an esteemed delegation from the IMNST, which included Prof. Sun Daoheng, Prof. Hou Liang, Prof. Zheng Gaofeng, Prof. Zhu Qingyuan, and other distinguished researchers. They were hosted by Guo Yunfa who showcased our lab facilities and shared insights into our latest research projects and technological achievements. We are grateful for their visit and look forward to future collaborations with IMNST toward advanced micro-/nano manufacturing science and technology.

Farewell BBQ

Over the coming weeks, we will be bidding farewell to several colleagues in the team as they end their stint at NUS, and there was no better way to celebrate their company other than a barbecue at West Coast Park. Our departing colleagues are Dr. Zhan Jiaming, Dr. Cai Yang, Zhang Baocai, and Yan Qi, while Xu Guiyin will return to NUSRI-CQ in Chongqing, China, to continue his PhD candidature.

New paper publications

This month we are proud to present new findings through 3 journal publications in Journal of the European Ceramic Society, ACS Applied Materials & Interfaces, and Tribology International.

Influence of water on the machinability of calcium fluoride crystal

J. Zhan, Y.J. Lee, S. Yang, H. Wang

Journal of the European Ceramic Society, 44(15)116738

Abstract:

Calcium fluoride (CaF2) optical components are produced by ultra-precision machining, but the often-neglected ambient water may potentially affect its processing. This work provides a systematic study on the role of water in the machinability of single-crystal CaF2. Micro-scratching experiments revealed poor machinability and reduced deformability under water adsorption. Atomic scratching simulations reproduced the mechanical deformation and identified the enhancement in dislocation nucleation with water, which led to the reduction in deformability due to dense cross-linking of dislocations. Atomic scale cutting simulations also identified easier formation of subsurface cracks under water adsorption. With the aid of mechanical schematic models based on the simplification of the scratching process, this work revealed that while water enhances the plastic flow of the material during machining, the accumulation of dislocations creates stress conditions sufficient to induce material fracture, which is a unique influence of water adsorption on the reduction in machinability of CaF2.

Triple Effects of the Physicochemical Interaction between Water and Copper and Their Influence on Microcutting

C. Zhang, Y.J. Lee, Y.F. Zhang, H. Wang

ACS Applied Materials & Interfaces, 16(28)37167–37182

Abstract:

Water has been recognized in promoting material removal, traditionally ascribed to friction reduction and thermal dissipation. However, the physicochemical interactions between water and the workpiece have often been overlooked. This work sheds light on how the physicochemical interactions that occur between water (H2O) and copper (Cu) workpiece influence material deformations during the cutting process. ReaxFF molecular dynamics simulations were employed as the primary method to study the atomistic physical and chemical interactions between the applied medium and the workpiece. Upon contact with the Cu surface, H2O dissociated into OH– ions, H+ ions, and traces of O2– ions. The OH– and O2– ions chemically reacted with Cu to form bonds that weakened the Cu–Cu bonds by elongation, while the H+ ions gained electrons and diffused into the Cu lattice as H– ions. The weakening of surface Cu bonds promoted plastic deformation and reduced the difficulty of material removal. Meanwhile, further addition of H2O molecules saw a plateau in hydrolysis and more dominance of H2O physical adsorption on Cu, which weakens the elongation of Cu–Cu bonds. While the ideal case for atomic-scale material removal was found with an optimal number of 240 H2O molecules, the presented Cu material state with more H2O molecules could account for the observations in microcutting. The constricted nature of physical adsorption and hydrogen ion diffusion in the surface layer prevented the propagation of dislocations through the surface, which subsequently caused pinning points to be closer together during chip formation as observed by smaller chip fold widths on the microscale. Theoretical and experimental analysis identified the importance of accounting for physicochemical interactions between surface media and the workpiece when considering material deformations at micronanoscale.

Modeling and analysis of surface integrity transition in cutting of Sip/Al composites based on coordination deformation effect of particle-matrix

Z. Zheng, D. Chen, K. Huang, J. Zhang, H. Wang, X. Chen, J. Xiao, J. Xu

Tribology International

Abstract:

With the wide application of Sip/Al composites in key fields, it is critical to understand the material removal behavior and surface integrity evolution mechanism of Sip/Al composites. In this paper, based on the nanoindentation and scratching experiments, the coordination deformation behavior of Si particles and the Al matrix were investigated at the micro-scale, and the mechanism and conditions of surface integrity transition (SIT) of Sip/Al composites were elucidated. Then, taking into account the feature of particle fragmentation and detachment caused by interfacial failure, an analytical model of specific cutting energy for Sip/Al composites cutting under different material removal modes was established. The competitive relationship between ductile deformation and surface defect formation was investigated, and a quantitative prediction model for the critical depth of SIT was proposed. The results show that the evolution of the material removal behavior of Sip/Al composites is a consequence of the coordination deformation the Al matrix and Si particles. The material removal mode of Sip/Al composites transitions from ductile removal to quasi-brittle removal with particle fragmentation and detachment, and there is an obvious SIT characteristic. The prediction results of critical depth are in agreement with the experimental results, with an average error of less than 9.8%. Moreover, an appropriate increase in cutting speed can effectively enhance the surface integrity of Sip/Al composites. This research contributes to a deeper understanding of the low-damage machining mechanism of Sip/Al composites.

PhD Candidature Invitation (priority for ASEAN countries)

We are looking for aspiring PhD candidates who are interested in pursuing research in the field of Artificial Intelligence for Manufacturing. A brief description on the research topic can be found in our Openings. Please contact Dr. Wang Hao (mpewhao@nus.edu.sg) if you are interested!